Page 4 of 6

Re: Firewall Project

Posted: Fri Jun 11, 2010 10:32 pm

by pro70z28

Re: Firewall Project

Posted: Sat Jun 12, 2010 7:51 pm

by pro70z28

Re: Firewall Project

Posted: Sun Jun 13, 2010 10:31 am

by John_Heard

Cool... Hey I want to borrow your shrinker! I need to make me some dzus rails... Which model you have?

Re: Firewall Project

Posted: Sun Jun 13, 2010 3:46 pm

by pro70z28

John_Heard wrote:Cool... Hey I want to borrow your shrinker! I need to make me some dzus rails... Which model you have?

I'm not sure. I bought it from a booth at a car show a few years ago. I think it's about the same deal as H.F. sells. It works good for what I use it for, although it marks up the metal some. From what I've been told the higher quality shrinker/stretchers don't do that?

Re: Firewall Project

Posted: Sun Jun 13, 2010 7:38 pm

by pro70z28

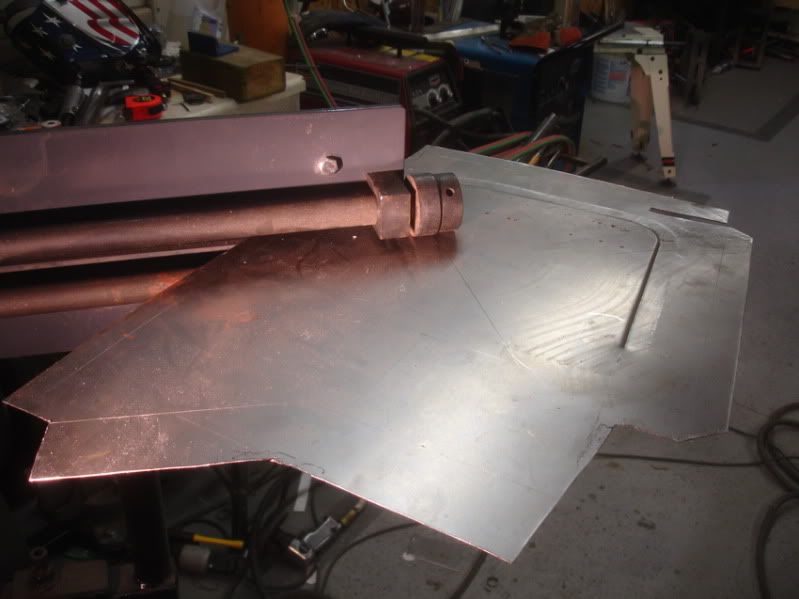

Added a couple more pieces to the puzzle this afternoon.

Re: Firewall Project

Posted: Sun Jun 20, 2010 9:42 pm

by pro70z28

Everybody (but me) had to work this weekend, we celebrated Father's day Thursday, so I had the weekend to work on the firewall. Got a fair amount done.

Since this WILL be a street legal car, I found a new spot to display the trim code tag.

I stuffed it between the strut tube & the inlet side of the intercooler.

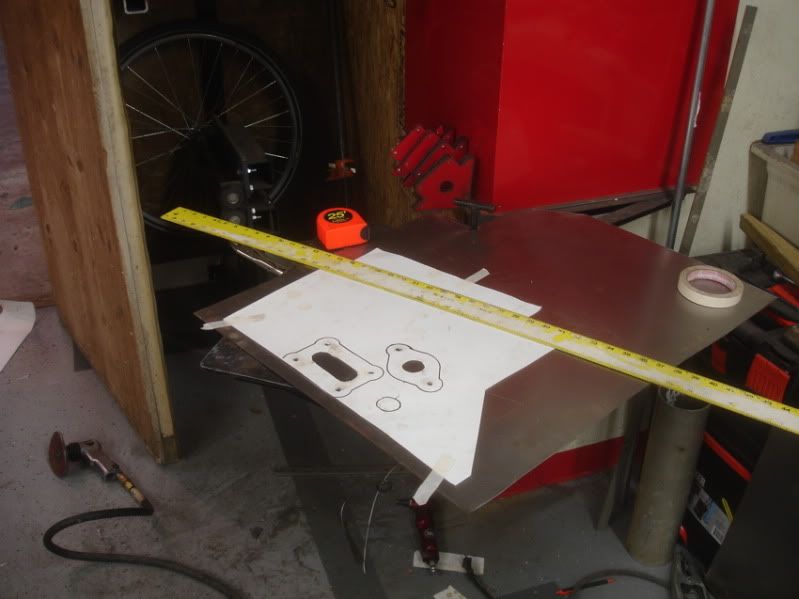

Also made paper patterns for a couple more pieces of the puzzle.

Re: Firewall Project

Posted: Sun Jun 20, 2010 9:43 pm

by pro70z28

I decided to stamp a "Camaro: logo in the driver's side panel

The press and bead rolling oil canned the panel a little but I think it will straighten out when I put the 7/8" tabs on the top & bottom with the brake.

It came out fairly clean, even the little piece in the top of the "o" stamped. That part was about 1/2 the size of a pencil eraser. When I paint the firewall I'll paint the logo over this, the stamping will give it a little extra "pop".

Re: Firewall Project

Posted: Sun Jun 20, 2010 10:05 pm

by vegaracer

I'm sure I've said it before, but you have some great skills.

That panel with "Camaro" in it is flawless.

Re: Firewall Project

Posted: Sun Jun 20, 2010 10:17 pm

by John_Heard

That is pretty cool, nice job..

Re: Firewall Project

Posted: Mon Jun 21, 2010 1:47 pm

by wikd69

pro70z28 wrote:I decided to stamp a "Camaro: logo in the driver's side panel

The press and bead rolling oil canned the panel a little but I think it will straighten out when I put the 7/8" tabs on the top & bottom with the brake.

It came out fairly clean, even the little piece in the top of the "o" stamped. That part was about 1/2 the size of a pencil eraser. When I paint the firewall I'll paint the logo over this, the stamping will give it a little extra "pop".

So help me understand how you're doing that:

You're using what looks like 3/16" aluminum on your CNC mill to create the Camaro pattern, then using it in some fashion in your press. Do you apply force to a heavy flat plate on top of the aluminum pattern, forming the pattern on sheet metal underneath which sits on a wooden panel ? Thats the only way I know of you could get the results you're getting, which btw, are fantastic.

What sort of press are you using, and how much force ? It would have to be pretty extreme I would suspect. Do you have pix of the pattern / piece / work setup arrangement ?

I would love to try this myself, though I certainly don't have your talent.

Re: Firewall Project

Posted: Mon Jun 21, 2010 2:10 pm

by pro70z28

Thanks everybody for the positive comments. I didn't take any pics. of this stamping but I did awhile back when I stamped out the sheet metal for the intercooler flanges.

The dies are CNC cut out of aluma-panel, a signboard that has a solid PVC core and is laminated on both sides with aluminum. (I used 3/4" MDF for the intercooler parts) Altogether the aluma-panel is just under 1/8" thick. I just use a H.F. 20 ton press & sandwich everything between some plate steel I got from the scrap yard. The aluma-panel dies are from scraps around the sign shop.

Re: Firewall Project

Posted: Mon Jun 21, 2010 2:20 pm

by wikd69

pro70z28 wrote:Thanks everybody for the positive comments. I didn't take any pics. of this stamping but I did awhile back when I stamped out the sheet metal for the intercooler flanges.

The dies are CNC cut out of aluma-panel, a signboard that has a solid PVC core and is laminated on both sides with aluminum. (I used 3/4" MDF for the intercooler parts) Altogether the aluma-panel is just under 1/8" thick. I just use a H.F. 20 ton press & sandwich everything between some plate steel I got from the scrap yard. The aluma-panel dies are from scraps around the sign shop.

I would guess the aluma-panel is soft enough that it naturally provides the nice smooth edge radius / transition for the pressed shapes outline, height wise. Very clever and very clean.

Re: Firewall Project

Posted: Mon Jun 21, 2010 5:40 pm

by pro70z28

The aluma panel looks the same when I take it out as before I used it . I would have thought the edges would have rounded off a little but not so. I leave an 1/8" space between dies so the aluminum naturally bevels at about a 45° angle.

Re: Firewall Project

Posted: Mon Jun 21, 2010 7:24 pm

by wikd69

pro70z28 wrote:The aluma panel looks the same when I take it out as before I used it . I would have thought the edges would have rounded off a little but not so. I leave an 1/8" space between dies so the aluminum naturally bevels at about a 45° angle.

Your top press plate looks to be right at 1" thick - is it thick enough to evenly spread the pressure or do you need to do multiple presses to get what you want ?

Re: Firewall Project

Posted: Mon Jun 21, 2010 7:26 pm

by pro70z28

Works in one stamp as long as I keep it under the plate about 8"x8".