This is important cuz I need to understand the amount of dynamic compression resulting from increased boost levels at WOT. I was really surprised by what I extrapolated out using Weiands published supercharger technical data.

I've been running the standard 9% underdrive for quite awhile and will change this to 1-to-1 during this current build cycle. As mentioned, this will bump my effective compression a bunch, and running 91 pump gas might be a problem at full tilt boogie. This is why I've started looking at water/methanol injection as a remedy for relatively low octane pump gas.

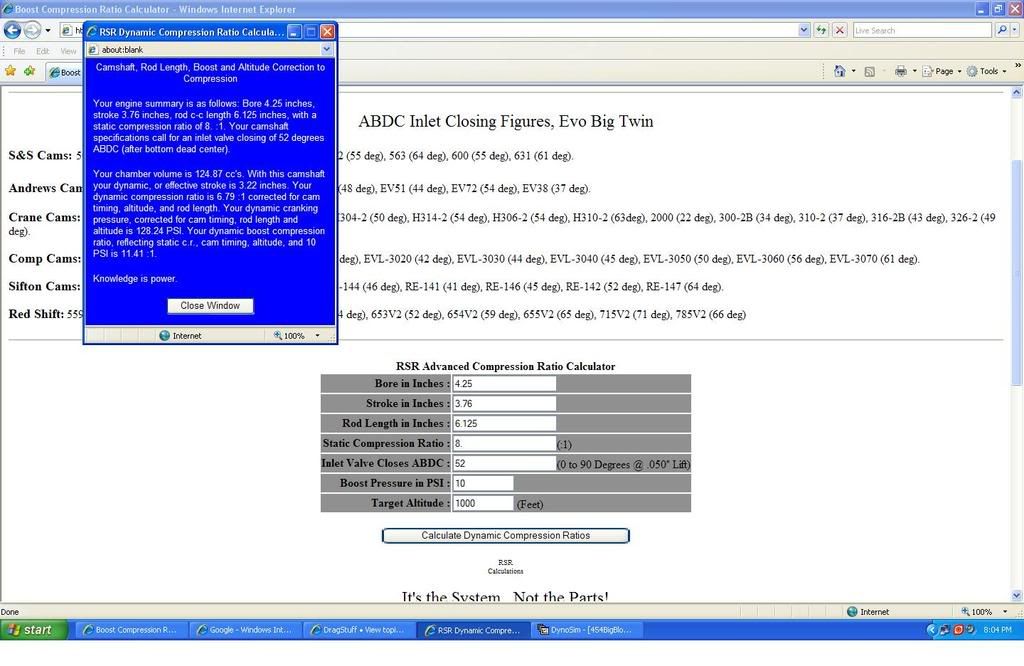

Here's my projections on my build, current and future.

You'll note the current run-state (9% under) yields about 8 lbs of boost, resulting in about 12.4 to 1 dynamic compression. This is just a swag number, cuz there's a number of other factors which would influence what the actual value should be. I'm just not smart enough to know what they are so like I said, this is a swag.

Bumping this up to 1 to 1, I should see around 10 lbs of boost and an effective 13.4 to 1 dynamic compression. This is where it would get really interesting with 91 octane pump gas on the street, though I'm not sure I have enough hair to stay in it that long on the street. Even today, the combination of wide open secondaries with lots of boost while driving on the street is enough to get your attention. Doing this with lots more boost and compression would be fun, in an I-almost-got-run-over-by-a-bus kind of way, ya know ?

Anyway, one of the points I wanted to make here is that this may be a perfect spot to introduce a managed and metered water/methanol injection system.

Have any of you guys out there with blowers or prochargers, et al, dealt with this to the point you could identify the benefit of water/methanol in a setting like this ? Bill, I think you said that you've added a system to your procharged 383.

Besides increasing stability of otherwise low octane pump gas under high compression, the spray also helps to cool the air charge in the manifold *and* gives you significantly more grunt at combustion time.

I think it would be an absolute hoot to try this. And it would be an even bigger hoot to just swap my current cogs and go to 9% over. I just need to determine whether or not I have enough roll cage in my ride.

Something to note: These numbers are specific to a 427. The boost numbers would be higher for a smaller displacement motor, lower for a higher displacement motor, etc.

Comments ? Feedback ? Criticisms ?